Safety Awareness – Preventing Strains in the Workplace

Posted on 03/22/22 by PMA Companies

Your employee, Chris, is unable to make it into work because of the sharp, debilitating pain shooting down his leg. His doctor just diagnosed him with sciatica stemming from a herniated disc—possibly resulting from the repetitive bending and lifting he does in his job. Chris will require physical therapy or surgery, or possibly both, and may experience continued pain and lost work time. Unfortunately, this is an all-too-common scenario in the workplace today. Strains can have a major impact on your employees and your workers’ compensation program.

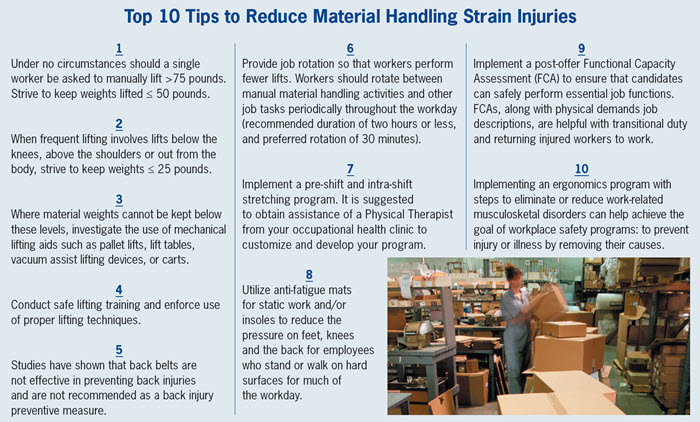

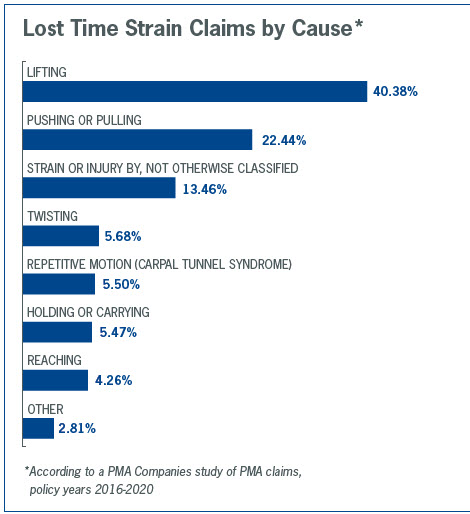

Lifting and pushing or pulling rank as both the top frequency and severity causes of lost time strain claims. According to a recent PMA Companies study, approximately 63% of lost time strain claim incurred dollars (policy years 2016 -2020) are attributable to these causes. Health services, manufacturing, social services and business services are the leading industries for strain claims.

Workers between the ages of 25 to 54 are incurring 67% of the lost time and medical only strains reported. The top two body parts most affected are the shoulders and lower back area, with knees and wrists coming in third and fourth place, respectively.

Though some actions may seem harmless—lifting a box, reaching for a tool, or even typing—there’s a risk for strains leading to musculoskeletal disorders (MSDs) in all industries. While some factors that contribute to the potential for employee injuries cannot be controlled, the good news is that others can be reduced or minimized. But first it’s important to understand how injuries can occur.

Types of Overexertion Injuries Leading to Strains

Strains can come on suddenly, but they may result from repetitive motion over time such as sitting at a desk for long periods. These physical “overexertion” injuries can be categorized as:

- Injuries from excessive physical effort or force: when an employee uses intense force in trying to lift or pull an object

- Injuries from repetitive motion: when an employee does a task repetitively, often part of a work process for weeks, months or years at a time

- Awkward postures: when an employee does an everyday motion the wrong way (or too suddenly) and puts inappropriate force on the wrong places of the body, causing injury

Employee Health Risk Factors

Although sometimes overlooked, there are individual health risk factors to consider when assessing the work environment. Workers who drink excessively, smoke, are obese, have poor posture and don’t take care of their health are at a higher risk of experiencing a strain. Employee nutrition, hydration and physical fitness all affect the possibility of developing a strain or consequent MSDs.

Implementing Controls

Consider the following to reduce strains in the workplace:

Workspace design: Consider conducting ergonomic assessments so that work areas are safe. Look at the height of the work to be performed. How can items be brought within easy reach? Using standing workstations with a footrest, cushioned floor mats and height-adjustable chairs or stools can help avoid injuries. Chairs for seated workstations should be fully adjustable as well. Frequently used tools should be kept close and in front of the body. If items are stored overhead, a ladder or stepstool should be provided for safe lifting conditions.

Work practice controls: Employees should keep their elbows as close to their bodies as possible while at work. Can they pause to stretch from time to time? Consider implementing a stretching program that helps to keep employees safe and fi t. Is it possible for employees to rotate jobs, thus reducing stress on one part of the body?

Education & training: Employees should learn how to prevent MSDs and enhance their individual health and wellness. This can include classroom training for specific jobs and tips on noticing the early warning signs of MSDs. It can also cover how to act quickly if a strain occurs (i.e., ice, compression, and elevation of the injured area to reduce swelling).

Cross-functional teams: Consider building a cross-functional team that has been trained in basic ergonomic principles and risk-factor identification to aid in preventing workplace injuries. When necessary, this team can brainstorm solutions to reduce or eliminate the risk factors that lead to injuries. They can also recommend ideas for improvements to management and assist with designing corrective actions.

A Proactive Approach

PMA Risk Control uses an ergonomic focus in preventing strains to minimize losses and reduce the frequency and severity of workers’ compensation claims. Our Ergonomics Practice Team can assist in studying past losses to identify trends, outliers and other data that are relevant to your organization’s “physical exertion” incidents. Our team members, who are certified in the ergonomic strain reduction process, use nationally recognized ergonomic assessment tools to evaluate and reduce the risks associated with challenging job tasks.

In addition to onsite and on-demand service consulting, PMA offers a specialty client webpage in PMA Websource® for education on ergonomics and strain reduction. This page includes access to our Office Ergonomics Assessment Tools and training.

If you have any questions or would like additional information, please contact your local PMA Risk Control Consultant or reach out to us at heretohelp@pmagroup.com.

IMPORTANT NOTICE

The information and suggestions presented by PMA Companies in this risk control technical bulletin are for your consideration in your loss prevention efforts. They are not intended to be complete or definitive in identifying all hazards associated with your business, preventing workplace accidents, or complying with any safety related or other laws or regulations. You are encouraged to alter the information and suggestions to fit the specific hazards of your business and to have your legal counsel review all of your plans and company policies. PMA Companies and Old Republic Companies do not provide legal advice and the information and suggestions in this bulletin should not be considered as such.